Tesla Resumes Use Of Millimetre Wave Radar

On June 7, 2022, Tesla filed materials with the FCC regarding millimeter wave radar.

Generally, RF-related products marketed in the US must submit third-party testing materials to the FCC to demonstrate compliance with US spectrum control rules.

This means that Tesla has not only not given up on millimetre wave radar, but has also taken it upon itself to design a millimetre wave radar.

In fact a year ago, on 3 June 2021, Tesla made a submission regarding a millimetre wave radar, the 2AEIM-161631, which is a relatively specific 60GHz-64GHz millimetre wave radar.

The purpose of this millimetre wave radar is currently unknown, and from the material vendor it appears that its main chip is Texas Instruments' IWR6843AOP, which may be Driver Vital Monitoring, i.e. monitoring the driver's heartbeat and pulse.

Although Musk says he is removing the car's forward-facing millimetre wave radar, it appears from the contents of the Tesla owner's manual that the millimetre wave radar has always been there and has never been removed.

In the US region, page 219 of the 2022 Tesla Model Y owner's manual clearly states.

"Traffic-Aware Cruise Control and Autosteer are unavailable because the radar located in the front bumper area of your vehicle has no or low visibility. Your vehicle is OK to drive. Traffic-Aware Cruise Control and Autosteer will remain unavailable as long as the radar lacks This could be a temporary obstruction caused by factors like snow, ice, dirt, or mud. If the alert is caused by a temporary factor like these, no action might be needed: the condition might clear during your drive.

As you can see, Tesla Smart Drive must be accompanied by millimetre wave radar.

This is also the case for the Model S Plaid, which will be launched in 2021.

The [6] in the picture stands for millimetre wave radar and, like the Model 3, the Model S Plaid is equipped with the ARS-4B from ASC, a subsidiary of Continental Motors, with an effective range of up to 170 metres. This is a product from early 2014, which is very cost effective and has been used by Tesla.

In the same period, ASC also launched the ARS-4A with an effective range of up to 250 metres, although it is a little more expensive. Most car companies have therefore opted for the ARS-4A.

In accordance with FCC practice, some of the information is confidential and the confidentiality restrictions are not lifted until six months later.

At the moment the FCC website only discloses the test report and Label label of the Tesla millimetre wave radar.

The only information available at this time is the approximate parameters, 3-wire access and a decent amount of power. Tesla's original Continental ARS-4B had a power output of just 52 milliwatts.

Tesla has had a series of complaints about ghost braking, the root cause of which is not the vision system, but may actually be the millimetre wave radar.

Millimetre wave radar is sensitive to metallic targets, particularly pedestrian bridges and roadside signs, and even central guardrails, and Tesla has ghost braked on several occasions. The head of Tesla's AI project - André Capasi - has described a typical Tesla 'ghost brake' caused by the 'camera + millimetre wave radar' technology route in a speech Case in point.

When the vehicle is about to go under a bridge, the millimetre wave radar has detected the presence of the 'bridge' as a static object, but because it does not have sufficient resolution, the millimetre wave radar cannot distinguish whether the object is a bridge or a car.

This is where visual perception is needed to tell the system what this static object really is.

But because of the associated millimetre wave radar, the camera is not sufficiently accurate in measuring all parameters of the object in front of it.

If there happens to be a slowly decelerating vehicle in front of you (but not enough to cause braking), the system correlates the 'decelerating vehicle' reported by the vision system with the 'static object' reported by the radar, resulting in an unnecessary braking event.

Most millimetre wave radars filter out static targets to avoid ghost braking. But the ARS-4B used by Tesla was originally designed for industrial use and does not filter static targets.

Then there is the fact that Tesla hides the millimetre wave radar inside the bumper for aesthetic reasons. If it were a high quality millimetre wave radar it wouldn't have much impact, but the ARS-4B is the lowest end millimetre wave radar for Continental cars, and its performance is already poor, and even worse when hidden.

The solution is simple: instead of removing the millimetre wave radar, replace it with a 4D millimetre wave radar.

Because vision systems tend to miss detection, millimetre wave radar, which filters out static targets, also tends to miss detection.

The essential difference between L3 and L2 autonomous driving is that the former tries to avoid showing shoulders, while the latter allows for missed detections.

Millimetre wave radar is far more accurate and reliable than vision systems when it comes to distance and speed measurement, and is an irreplaceable presence.

Tesla has always been bold, even so, and would not dare to do away with millimetre wave radar.

Continental's ARS540 and Bosch drop-in band millimetre wave radar are the only 4D millimetre wave radars currently available, and they perform perfectly.

But there are drawbacks, one being the high price.

The price difference between Continental's ARS4A and ARS4B is no more than $50.

Secondly, the two 4D millimetre wave radars have the disadvantage that they have a bulging back, which makes them too high.

This means that the 4D millimetre wave radar can only be used on new vehicles if the vehicle is not yet styled and a mounting position can be found for the radar.

The best performing 4D millimetre wave radar available: Continental's ARS540 with a big bump on the back

So Tesla had to take matters into its own hands and make its own millimetre wave radar.

The technical threshold for 4D imaging millimetre wave radar is actually quite low, thanks largely to Texas Instruments.

Texas Instruments launched a highly integrated 77GHz millimeter-wave radar chip based on CMOS processes at the end of 2016 - the AWR1642 series for short- and medium-range scenarios - which integrates three modules - front-end MMIC RF, DSP and MCU - on a single 77GHz millimeter-wave radar SoC chip, significantly reducing The AWR1642 series integrates three front-end MMIC RF, DSP and MCU modules into a single 77GHz mmWave radar SoC chip, significantly reducing the cost of mmWave radar and significantly lowering the hardware development difficulty of in-vehicle mmWave radar.

For close-range scenarios, TI has created a more integrated antenna-on-a-chip (AoP) chip, which integrates the antenna into the chip and the most difficult planar printed antenna, bringing the price of millimeter wave radar down to the hundred dollar level.

Compared to other radar chip manufacturers, TI chip development is foolproof, the underlying software development is complete, the tool chain is also easy to get started, and any RF engineer who has been in the industry for two years can basically handle a millimeter wave radar design alone.

This has given rise to a large number of start-up millimeter wave radar companies.

Over time, however, TI found that the millimeter-wave radar chipset market, which was virtually monopolized by NXP and Infineon, had not changed, so TI took a different approach and pushed the 4D imaging millimeter-wave radar concept.

Basically, at the end of 2018, it will offer a complete design for a 4-chip cascaded 4D millimeter-wave radar based on the AWR2243, including the most difficult antenna to handle, which is also considered to be able to embed a 4-element series-fed patch antenna.

The algorithms are available in both MATLAB MIMO and beamforming options, making the 4D imaging millimetre wave radar a turnkey project with no technical barriers.

At the same time, Continental, the dominant millimetre wave radar player, was also developing a 4D imaging millimetre wave radar, having actually sensed in 2015 that conventional 3D (i.e. speed, distance and azimuth, which is the data provided by conventional millimetre wave radars) millimetre wave radars had come to an end.

The development of the ARS540 started in 2016 with an initial design using two S32R274s from NXP, but this posed some problems; the two S32R274s resulted in a PCB area that was too large for an automotive radar, which is intended to be as small as possible, while the front-end sensor fusion required a relatively high bandwidth; Continental's initial design used a MIPI CSI3 with a bandwidth of 14.88Gbps, which is better than our commonly used MIPI CSI2, of which the S32R274 is a MIPI CSI2.

But there are very few chips that support MIPI CSI3. In addition, Continental wanted the ADC to be more accurate so that the high resolution would be practical, and the synchronisation of the clocks between the two chips was a bit tricky, so Continental decided to use Xilinx's Zynq UltraScale+ RFSoC family of FPGAs.

Xilinx's Zynq UltraScale+ RFSoC family of FPGAs is designed specifically for the RF domain and contains internal ultra-high precision ADCs and DACs, with a choice of 12 and 14 bit grades and up to 16 ADCs or DACs.

Normally ASICs do not have such a luxurious configuration of ADCs and DACs for cost reasons, and the S32R274 contains only four 12-bit ADCs with a sample rate of 10Msps.

Having been replaced by an FPGA, NXP has also started work on a chipset for 4D imaging millimetre wave radar.

In December 2020, NXP introduced the S32R45 4D imaging millimetre wave radar signal processor and the TEF82xx transceiver, adding an option to the 4D imaging millimetre wave radar chipset, which is likely to be introduced by Infineon and Analog Devices in the future.

The ARS540 uses a 4-chip cascade of four NXP 77GHz millimetre wave radar transceivers (i.e. MMICs) MR3003, each MR3003 is 3 transmits and 4 receivers, making 4 chips 12 transmits and 16 receivers.

The vast majority of millimetre wave radars today use a single transceiver, usually only 3 transmitting and 4 receiving, i.e. only 12 virtual channels, whereas the ARS540 has 192 virtual channels and much higher resolution. It can be called an image radar.

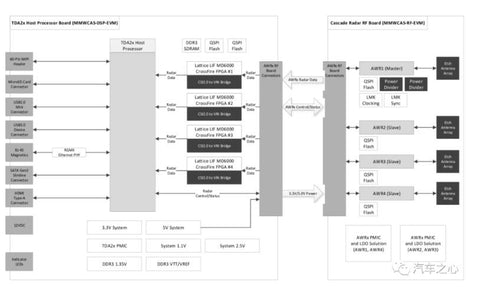

TI's solution is the same, except that the MR3003 is replaced by the AWR2243 and the FPGA by the TDA2x.

Apart from Continental, 4D imaging millimetre wave radars in China and worldwide are basically based on TI's cascade solutions, ranging from 2-chip cascades for low cost to 4-chip cascades for performance.

Huawei's 12-transmitter, 24-receiver 4D imaging millimetre wave radar, according to sources, is based on its own chip, which is supposed to be a cascade of four 3-transmitter, 6-receiver transceivers, but it could also be a six-chip cascade of Texas Instruments' AWR1642, which is a 2-transmitter, 4-receiver.

Let's look at the Texas Instruments solution, which provides a full set of circuit diagrams.

Texas Instruments 4D Imaging Millimeter Wave Radar Development Board Frame Diagram

Texas Instruments 4D imaging millimetre wave radar with embedded 4-element series-fed patch antenna uses the industry's highest quality Rogers RO3003 PTFE carrier board.

The ARS540 is the only millimetre wave radar that can actually measure the height of the target, i.e. its vertical resolution Elevation is higher, at 2.3°, much higher than the Texas Instruments solution, after all Continental has designed its own antenna and has over 20 years of experience, and the MR3003 is indeed stronger.

From this point of view, the ARS540 is still the only 4D millimetre wave radar in the world.

Of course, it would have been better if we didn't use Texas Instruments' embedded antenna and designed it ourselves, but it would have taken a long R&D cycle and tens of millions of RMB in R&D equipment and facilities, and startups certainly don't invest in fixed assets in such a big way.

Height measurement with the ARS540

What does imaging millimetre wave radar look like?

The image above, taken from a Texas Instruments development board manual, is a millimetre wave radar image of a bicycle and a pedestrian at a distance of 1.5 metres from the vehicle. If it were a normal 3-frequency, 4-receiver monolithic 3D millimetre wave radar, the bicycle would only be detected as a dot, if at all.

Even with an imaging millimetre wave radar, a pedestrian is only a small dot, while a normal radar would not detect it at all, because metal reflects electromagnetic waves far better than the human body.

Clearly imaging millimetre wave radar is no match for LIDAR imaging.

As for Bosch's fifth generation millimetre wave radar, no details are available yet, but it is certainly a 4D radar, and its performance is probably not inferior to Continental's ARS540, which has a bandwidth of 76.065-76.932 GHz, nearly 900 MHz, and the ARS540 is still 500 MHz.

The downside of the Bosch may be the high power consumption, with an impressive 5495 milliwatts of RF output power and an estimated 20-40 watts of overall power consumption. the ARS540 has an RF output power of 1143 milliwatts.

Tesla's three lines combined are 356 milliwatts, which presumably means that Tesla has compromised on effective distance.

By December 4 of this year, the FCC will release photos of the internal disassembly of Tesla's millimeter wave radar and the composition of the components and even the circuit diagram.